A stainless steel filter is a type of filtration device made from high-quality stainless steel, designed to separate solid particles from liquids or gases. Known for its durability, resistance to corrosion, and ease of cleaning, it is widely used in industries such as food and beverage, pharmaceuticals, chemical processing, and water treatment. Stainless steel filters come in various designs, including mesh, disc, and cartridge types, depending on the application. They offer good filtration efficiency, high flow rates, and long service life, making them ideal for both high-pressure and high-temperature environments. Regular maintenance ensures good performance and longevity.

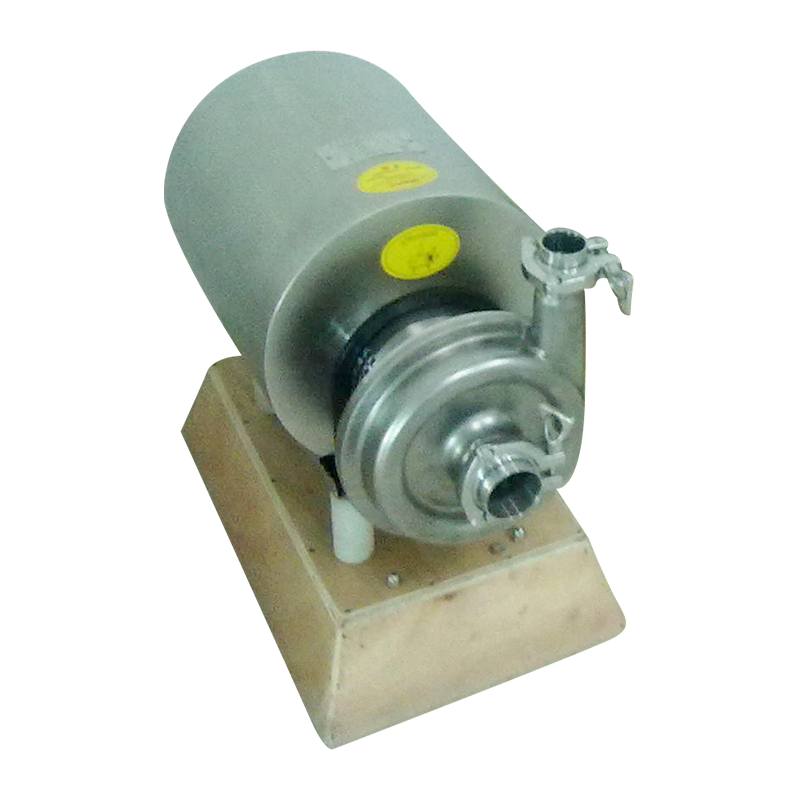

Material Considerations for Liquid Centrifugal Pumps

A liquid centrifugal pump is a mechanical device used to move fluids by converting rotational kinetic energy into hydrodynamic energy. These pumps are widely used in various industries including water treatment, chemical processing, pharmaceuticals, and food production. The primary function of a centrifugal pump is to transport liquids efficiently from one location to another.

The working principle involves a rotating impeller that spins within a casing, creating centrifugal force. This force pushes the liquid outward from the center of the impeller to the pump’s discharge outlet. As a result, the liquid gains velocity and pressure, allowing it to flow through piping systems.

Liquid centrifugal pumps are valued for their simple design, ease of operation, and ability to handle a wide range of fluids, including clean, dirty, and viscous liquids. They typically consist of components such as the impeller, pump casing, shaft, and seals, all designed to ensure reliable and leak-free operation.

These pumps come in various sizes and configurations, including single-stage and multi-stage models, to accommodate different flow rates and pressure requirements. Maintenance is generally straightforward, involving inspection of seals, bearings, and impellers to ensure continued performance.

Material selection is important for centrifugal pumps, especially when handling corrosive or abrasive liquids. Stainless steel and other corrosion-resistant materials are often used to enhance pump durability.

Overall, liquid centrifugal pumps provide a dependable solution for moving liquids in many industrial processes, offering efficiency and adaptability across various applications.

Material Selection for Valves and Fittings in Industrial Use

Valves and fittings are essential components in piping systems, used to control, direct, and connect the flow of fluids. They are common in industries such as chemical processing, water treatment, pharmaceuticals, and food production.

Valves regulate fluid flow by opening, closing, or partially obstructing passageways. Different types of valves include ball valves, gate valves, butterfly valves, and check valves, each designed for specific functions and flow control requirements. Valves help maintain system pressure, prevent backflow, and enable isolation for maintenance or safety purposes.

Fittings are used to join sections of pipe or tubing and to change the direction or diameter of the flow path. Common fittings include elbows, tees, reducers, couplings, and flanges. They ensure leak-proof connections and facilitate system assembly and disassembly.

Both valves and fittings are available in various materials such as stainless steel, brass, PVC, and other alloys to suit different fluid types and environmental conditions. Material choice depends on factors like corrosion resistance, pressure rating, and temperature tolerance.

Proper installation and maintenance of valves and fittings are critical to ensure system integrity and performance. Regular inspection helps detect leaks, wear, or damage, allowing timely repairs.

In summary, valves and fittings play a vital role in managing fluid flow and maintaining the functionality of piping systems across multiple industries.