A concentrate tank is a vessel used to store concentrated liquids or semi-liquids that are typically produced through processes such as evaporation, filtration, or extraction. These tanks are commonly found in industries like food and beverage, pharmaceuticals, and chemicals, where high-concentration substances need to be stored before further processing or dilution. Concentrate tanks are designed with features such as agitation systems to maintain uniformity and prevent settling, as well as temperature control systems to preserve the quality of the concentrate. Constructed from corrosion-resistant materials like stainless steel, these tanks are essential for efficient and safe storage.

Design Features of Pharmaceutical Concentrate Tanks

A pharmaceutical concentrate tank is an important piece of equipment used in the pharmaceutical industry to store concentrated liquids or solutions during the manufacturing process. These tanks hold active ingredients or intermediates that require careful handling to maintain their quality and stability before they are diluted or further processed.

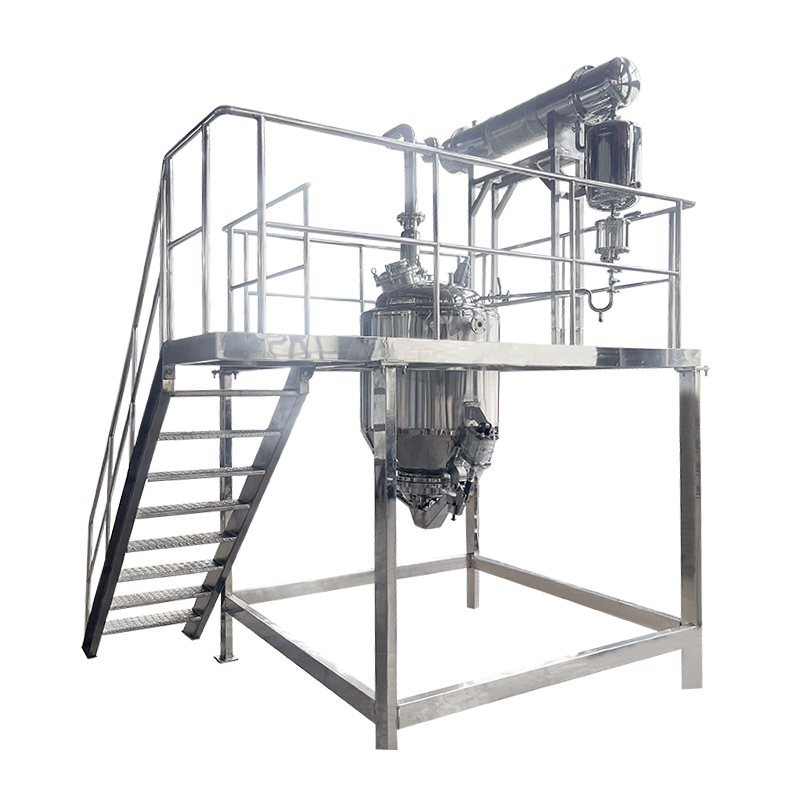

Pharmaceutical concentrate tanks are typically constructed from stainless steel due to its resistance to corrosion and ease of cleaning, which helps maintain a sterile environment. The tanks often have smooth internal surfaces to prevent contamination and facilitate thorough cleaning and sterilization.

These tanks usually include agitation systems to keep the concentrate uniformly mixed and prevent settling or separation. Temperature control features, such as heating or cooling jackets, may also be present to maintain good conditions for the stored materials.

The size and design of pharmaceutical concentrate tanks vary depending on production needs and the type of concentrate stored. Some tanks operate under controlled pressure conditions to support specific chemical processes or to protect sensitive ingredients.

Pharmaceutical concentrate tanks often integrate monitoring systems to track parameters like temperature, pressure, and mixing speed. These features help ensure consistent product quality and assist in compliance with industry regulations.

Overall, pharmaceutical concentrate tanks are critical for managing sensitive materials during pharmaceutical manufacturing, helping to ensure that final products meet required quality standards.

Key Design Elements of Medical Concentrate Tanks

A medical concentrate tank is a specialized vessel used to store concentrated medical liquids or compounds during the production of medical products such as medications, vaccines, or diagnostic reagents. These tanks are designed to maintain the integrity and purity of sensitive materials in controlled environments.

Medical concentrate tanks are commonly made from materials like stainless steel, which offers durability, corrosion resistance, and ease of cleaning. The smooth interior surfaces reduce the risk of contamination and enable thorough sterilization, meeting the hygiene standards required in medical manufacturing.

Agitation or mixing systems are often incorporated to maintain uniform consistency and prevent the settling of solids or separation of components within the concentrate. Additionally, temperature control features, including heating or cooling jackets, help preserve the chemical stability and activity of the stored substances.

These tanks may vary in size from small laboratory units to larger industrial vessels, depending on production scale. Some medical concentrate tanks operate under pressure or vacuum conditions to meet specific process requirements.

Routine cleaning, sterilization, and maintenance procedures are necessary to support the safe operation of medical concentrate tanks. Proper management of these tanks plays a vital role in producing safe and effective medical products.

In summary, medical concentrate tanks provide a reliable environment for storing sensitive medical concentrates, helping manufacturers maintain quality and safety throughout production.