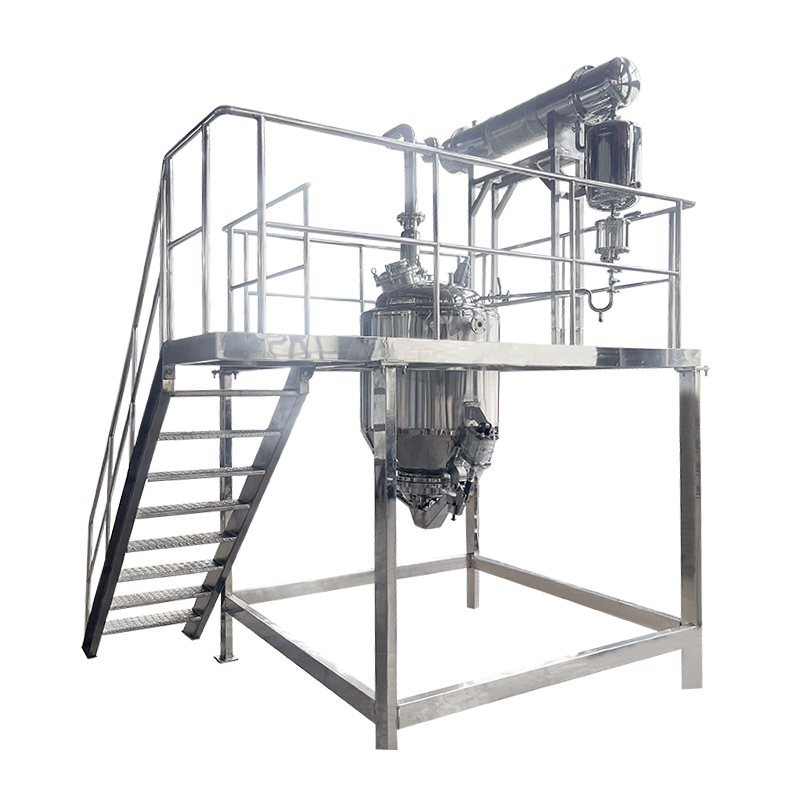

A liquid preparation tank is a vessel designed for mixing, heating, and storing liquids in various industrial processes. It is commonly used in industries such as chemicals, pharmaceuticals, food and beverage, and cosmetics. The tank often includes features like agitators to ensure thorough mixing and heating jackets for temperature control. Constructed from materials resistant to corrosion, these tanks maintain the quality and consistency of liquid formulations. Liquid preparation tanks support efficient production by providing a controlled environment for blending ingredients before further processing or packaging.

Materials and Design Considerations for Pharmaceutical Tanks

A pharmaceutical equipment tank is an essential component in the pharmaceutical manufacturing process. These tanks are designed to hold, mix, and process various liquid or semi-solid pharmaceutical ingredients under controlled conditions. They help ensure the quality, safety, and consistency of pharmaceutical products.

Pharmaceutical tanks are typically made from high-grade stainless steel or other materials that meet strict hygiene and corrosion resistance standards. The smooth, polished surfaces prevent contamination and facilitate easy cleaning and sterilization, which are critical in pharmaceutical environments.

These tanks often feature agitators to mix ingredients uniformly and heating or cooling jackets to maintain precise temperature control. Maintaining the correct temperature during processing can influence the chemical stability and effectiveness of the final product.

Pharmaceutical equipment tanks come in different sizes and configurations depending on the scale of production and the specific requirements of the process. Some are designed to operate under pressure or vacuum conditions to support various manufacturing steps such as dissolution, blending, or fermentation.

Routine maintenance, cleaning, and validation procedures are necessary to ensure the tanks perform reliably and meet quality assurance guidelines. Proper use of pharmaceutical equipment tanks supports efficient production while ensuring products are safe for consumer use.

In summary, pharmaceutical equipment tanks are critical for maintaining the integrity and consistency of pharmaceutical products during manufacturing.

Key Components and Features of Medical Equipment Tanks

A medical equipment tank is designed for use in healthcare-related manufacturing and processing, providing a safe and controlled environment for handling medical fluids and substances. These tanks are commonly used in the production of medical devices, diagnostics, and pharmaceutical preparations.

Constructed from materials such as stainless steel or specialized polymers, medical equipment tanks are built to meet hygiene standards required in medical and laboratory settings. Their design focuses on preventing contamination and allowing thorough cleaning and sterilization.

Medical tanks often incorporate features such as agitators for mixing, temperature control systems for heating or cooling, and pressure regulation to accommodate different medical processes. These features help maintain the stability and efficacy of medical formulations.

Sizes and configurations vary depending on the intended application, ranging from small laboratory-scale tanks to large industrial vessels. Some medical equipment tanks are designed for sterile environments, with sealed lids and fittings to prevent exposure to external contaminants.

Sensors and automated controls may be integrated to monitor and adjust operating conditions, ensuring consistent quality during production or processing. This is important in medical applications where precision and reliability are essential.

Overall, medical equipment tanks are vital tools in healthcare manufacturing, contributing to the production of safe and effective medical products.