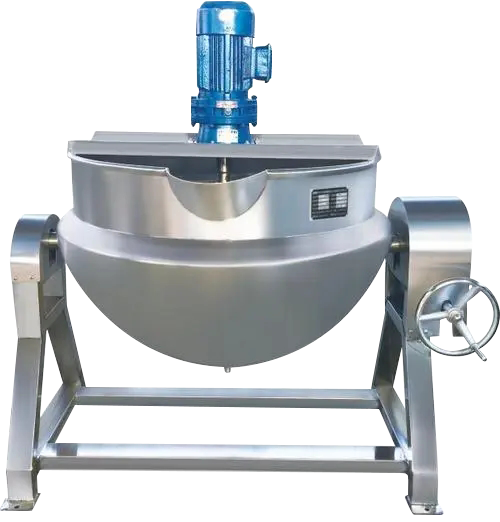

A Jacketed Kettle is a specialized cooking vessel designed with a double-walled structure, where the space between the walls—called the jacket—is used to circulate heating or cooling fluids such as steam, hot water, or thermal oil. This design allows for even and controlled temperature distribution throughout the kettle, preventing localized overheating and ensuring consistent cooking or heating of the product inside. Commonly made from stainless steel, jacketed kettles are widely used in food processing for preparing sauces, soups, creams, and other liquid or semi-solid products. Many models include built-in agitators to maintain uniform mixing and prevent scorching. The jacketed construction also enables rapid heating and efficient energy use while maintaining sanitary conditions through smooth surfaces that are easy to clean.

Key Benefits of Using Stainless Steel Jacketed Kettles

A Stainless Steel Jacketed Kettle is a versatile cooking and mixing vessel commonly used in food processing, pharmaceutical, and chemical industries. It consists of a main kettle body surrounded by a jacket or double wall through which heating or cooling media can circulate. This design allows for even temperature distribution and precise control during the heating or cooling process.

The stainless steel construction offers resistance to corrosion, ease of cleaning, and maintains sanitary conditions. The smooth interior surface smalls product sticking and supports hygienic operation, which is essential for food and pharmaceutical applications.

Jacketed kettles are used for cooking, heating, mixing, and blending various liquid or semi-solid products such as sauces, soups, creams, and chemicals. The jacket can be supplied with steam, hot water, or thermal oil depending on the temperature requirements of the process.

Many stainless steel jacketed kettles come equipped with agitation systems that help maintain uniform product consistency and prevent localized overheating or scorching. The tanks may also feature safety valves, temperature sensors, and easy-to-use controls.

In summary, stainless steel jacketed kettles provide an efficient and hygienic solution for processes requiring controlled heating or cooling, supporting a wide range of industrial applications.

Efficient Heating with Stainless Steel Steam Jacketed Kettles

A Stainless Steel Steam Jacketed Kettle is a specialized vessel designed for efficient heating of food or chemical products using steam as the heat transfer medium. The kettle consists of a double-walled stainless steel body with a hollow jacket where steam circulates to provide indirect and uniform heating.

The use of steam allows rapid and even heat distribution, which is ideal for cooking sauces, soups, jams, and other viscous materials. The stainless steel surface inside the kettle supports sanitary processing and easy cleaning, meeting hygiene requirements in food and pharmaceutical industries.

Steam jacketed kettles often include mixing or agitation mechanisms to ensure uniform temperature and prevent burning or sticking of contents during heating. They may also incorporate safety features like pressure relief valves and temperature controls for operational safety.

This type of kettle supports precise temperature regulation by controlling steam pressure and flow, enabling consistent product quality. The indirect heating method reduces the risk of localized overheating compared to direct flame or electric heating.

In conclusion, stainless steel steam jacketed kettles provide an effective and hygienic method for heating and cooking in various industrial processes, combining efficient heat transfer with sanitary design.