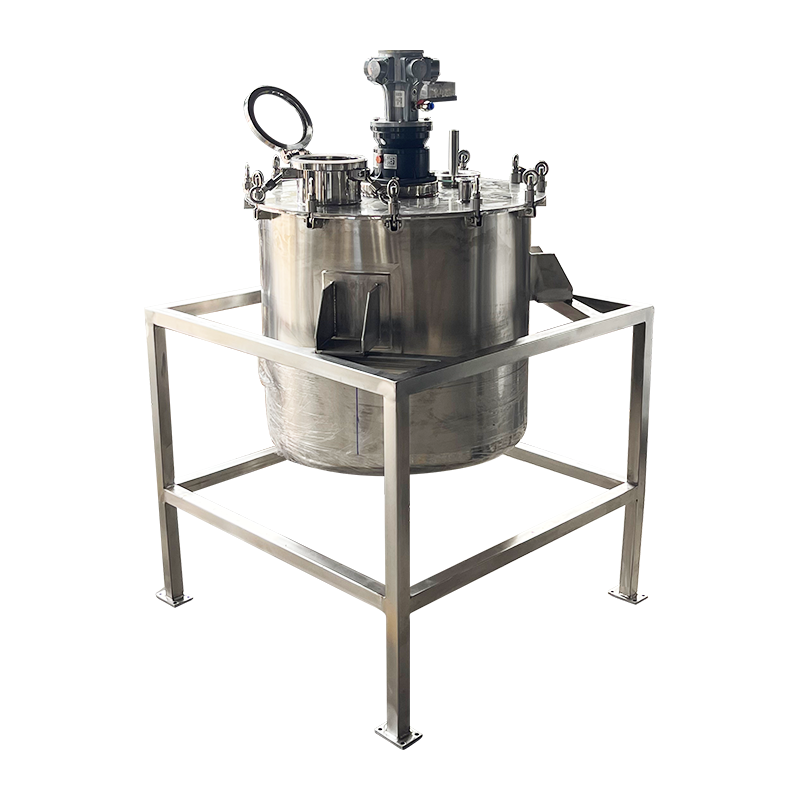

An electric heating mixing tank is a vessel designed for heating and blending liquids or semi-solids in various industries. It uses electric heating elements to provide precise temperature control, ensuring uniform heating throughout the tank. The tank is equipped with an agitator or mixer to promote consistent mixing of ingredients, improving product quality. Commonly made from stainless steel, it offers durability and corrosion resistance. These tanks are used in food processing, chemical manufacturing, pharmaceuticals, and cosmetics for processes like dissolving, blending, and heating. Electric heating mixing tanks enhance efficiency by combining heating and mixing in one unit.

The Importance of Agitators in Chemical Mixing Tanks

A chemical mixing tank is an essential piece of equipment used in various industries such as chemicals, pharmaceuticals, food processing, and cosmetics. Its primary function is to combine different substances or ingredients into a homogeneous mixture under controlled conditions. The tank typically features an agitator or mixer that helps achieve uniform mixing, preventing the separation of components during processing.

Chemical mixing tanks are made from materials that resist corrosion and are compatible with the chemicals being mixed, often stainless steel, which ensures the longevity of the equipment. The tanks can come in a variety of sizes and configurations, depending on the scale of production, and may be equipped with heating or cooling jackets to regulate temperature during the mixing process.

The agitator design can vary depending on the nature of the materials being mixed. For instance, tanks handling viscous or heavy-duty materials might use slower, more powerful agitators, while lighter, less dense substances may require faster, more gentle mixing.

One of the key factors to consider when using a chemical mixing tank is its ability to maintain the consistency and quality of the final product. The tank’s capacity, mixing speed, and temperature control must all be carefully managed to ensure the desired outcome.

Precise mixing is critical to product efficacy, while in food processing, consistency and quality are paramount. In summary, a chemical mixing tank plays a vital role in producing consistent, high-quality products in various manufacturing sectors by providing effective and reliable mixing capabilities.

Choosing the Right Chemical Blending Tank for Consistent Results

A chemical blending tank is designed to combine multiple chemical substances into a uniform blend. This equipment is commonly used in chemical production, pharmaceuticals, food and beverage industries, and even in the creation of cosmetics. The main purpose of the blending tank is to facilitate the thorough mixing of raw materials to create a consistent final product.

The tank is typically constructed from materials such as stainless steel to withstand corrosion and the chemical reactions involved in the blending process. These tanks often come with an internal mixing mechanism, such as an agitator, to ensure that all components are evenly distributed and properly mixed.

A key feature of chemical blending tanks is the ability to incorporate temperature control through heating or cooling jackets. This is important when working with substances that require specific temperature conditions for proper blending, ensuring that all reactions occur within safe and effective parameters.

Blending tanks come in various sizes and configurations, allowing for flexibility in different production environments. In the food and beverage industry, for example, blending tanks are used for combining ingredients like oils, flavorings, and emulsifiers to create consistent formulations. In pharmaceuticals, these tanks help blend raw materials to create precise compounds for medication.

Overall, chemical blending tanks are a vital part of manufacturing processes where consistent and accurate blending of materials is required to achieve high-quality products.