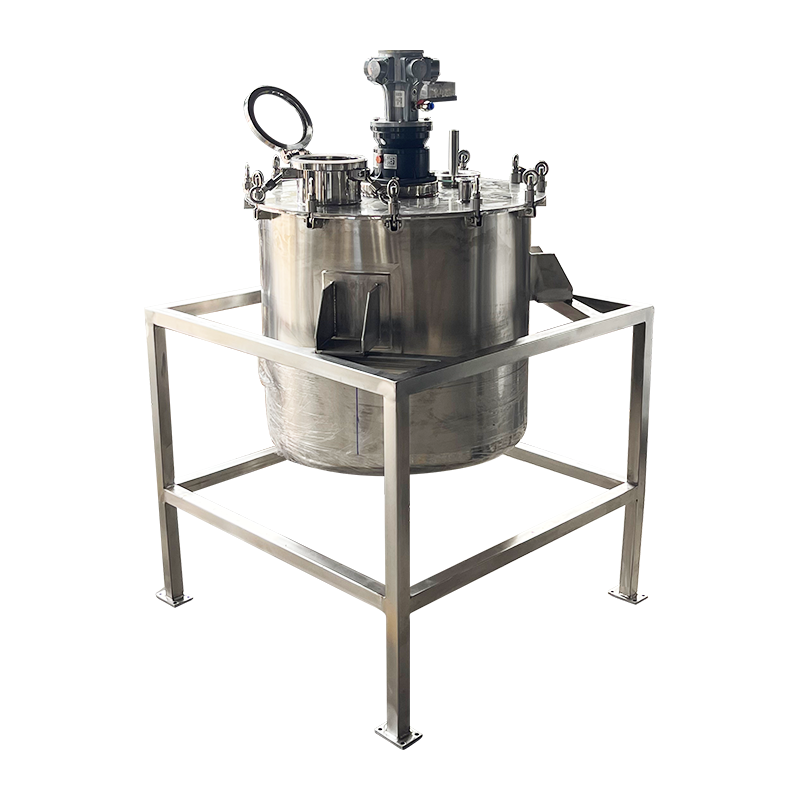

A Chemical Equipment Tank is a storage or processing vessel designed to safely hold and manage various chemicals used in industrial applications. These tanks are typically made from materials resistant to corrosion and chemical reactions, such as stainless steel, polyethylene, or fiberglass. They come in different shapes and sizes to suit specific process requirements and may include features like agitation systems, heating or cooling jackets, and safety valves. Chemical equipment tanks are used in industries like pharmaceuticals, manufacturing, and water treatment to ensure secure containment and controlled handling of chemical substances while maintaining safety and operational efficiency.

Safety and Maintenance of Chemical Holding Tanks

A Chemical Holding Tank is a container designed to store chemical liquids safely and securely before they are used in a process or transferred to other equipment. These tanks are widely used in industries such as chemical manufacturing, water treatment, and pharmaceuticals. The primary purpose of a chemical holding tank is to provide a temporary storage solution that ensures chemical integrity and prevents leaks or spills.

Chemical holding tanks are typically constructed from materials compatible with the stored chemicals, such as polyethylene, stainless steel, or fiberglass. The choice of material depends on the chemical’s properties, including corrosiveness, temperature, and reactivity. Proper material selection helps maintain the tank’s durability and safety.

These tanks often include features like level indicators, vents, and access ports to facilitate monitoring and maintenance. Some may also have heating or cooling jackets to maintain specific temperature requirements for the stored chemicals. Safety considerations such as secondary containment or spill prevention devices may also be incorporated to reduce environmental risks.

In addition to storage, chemical holding tanks can be used in process systems where chemicals require holding times for reactions or settling. Proper handling and maintenance of these tanks are essential to ensuring operational efficiency and safety.

In summary, chemical holding tanks serve as important components in chemical processing by providing reliable and safe storage for liquids during various stages of production.

Maintenance and Inspection of Self Bunded Chemical Tanks

A Self Bunded Chemical Tank is a type of storage tank designed with a built-in containment system to prevent chemical spills and leaks. This design integrates a primary tank inside a secondary outer tank or bund, providing double containment in one compact unit. Self bunded tanks are commonly used in industries such as chemical manufacturing, agriculture, and waste management.

The primary advantage of self bunded tanks is their ability to contain spills within the outer bund without requiring additional external containment structures. This reduces installation space and simplifies compliance with environmental regulations regarding spill prevention.

These tanks are generally made from corrosion-resistant materials like polyethylene, stainless steel, or carbon steel with protective coatings. The choice depends on the stored chemical’s nature and the environmental conditions.

Self bunded tanks may include features such as pressure relief valves, level gauges, and access points for inspection and maintenance. Some designs allow for easy transport and installation, making them suitable for both fixed and mobile applications.

The integrated bund also helps protect the environment by small risks of soil and water contamination in case of leaks. Additionally, maintenance and inspection are more straightforward compared to separate bunded systems.

Overall, self bunded chemical tanks offer a practical and efficient solution for safe chemical storage, combining containment and storage in a single unit.